Quality in the Nuclear sector

Introduction

Starting from the assumption that the analysis of what is done in one sector may benefit another sector by providing tips and guidance on improving work processes and quality management in general – benefits of benchmarking -, this article aims to present some of the main approaches that are used in the nuclear industry and that can inspire positive changes in construction.

The construction industry can be divided into smaller areas – examples are engineering or maintenance – and into further divisions - public contracts, private contracts, development projects, maintenance projects – this is also true for the nuclear industry that embeds:

- Engineering

- Construction

- Production/Operation

- Maintenance

- Decommissioning

The table below tries to match the main activities in both industries.

| Construction industry | Nuclear industry |

| Engineering | Engineering |

| Construction | Construction |

| Estate management | Production/Operation |

| Maintenance | Maintenance |

| Demolition | Decommissioning |

Table 1 - Main activities in the construction and the nuclear industries

Because the main activities appear the same, apparently the quality requirements should be similar. A better analysis of the characteristics of each industry, though, highlights that the differences are various and substantial.

The construction industry can be confined to a territory – i.e., a nation -, with specific characteristics. The UK way of building houses is quite different from the typical Italian one, where concrete and rebars are the basics of any family house – which is usually an apartment in a multistorey building.

When it comes to the Nuclear industry, the geographical distance does not play an important role in defining what methodologies are to be used. A nuclear reactor can be designed in Japan and installed in the USA. What plays a role is, eventually, the technology of the reactor or the requirements to be respected. As an example, the well-known Chernobyl reactor is based on technology not anymore in use in modern reactors.

Technological and scientific advancement play a critical role in the nuclear industry. Furthermore, there are only a few nuclear engineering companies and the nuclear plants operators are even less. But, they are quite well connected to one another, both directly as they may share interests in the same power plant or because they are under the surveillance of international authorities. The IAEA – International Atomic Energy Agency – is “the world's central intergovernmental forum for scientific and technical co-operation in the nuclear field. It works for the safe, secure and peaceful uses of nuclear science and technology, contributing to international peace and security and the United Nations' Sustainable Development Goals….The IAEA works in close partnership with Member States, United Nations agencies, research organisations and civil society to maximise the contribution of nuclear science and technology to the achievement of development priorities.” (IAEA, 2022). It is hard to think about anything similar in the construction industry. Knowledge management is kept at the core of the industry. As the CQI Nuclear Special Interest Group (2013) reminds us, there are three types of knowledge:

- Explicit knowledge – is the knowledge available through manuals, codes, drawings, et al.

- Implicit knowledge – is known to individuals and has the potential to be codified but has not yet been articulated or documented.

- Tacit knowledge – what is held in the mind of individuals and maybe unspoken and difficult to share. Examples are skills, intuition and judgement. Probably, this is most of the knowledge in any organisation.

The nuclear industry strives to reduce the knowledge gap to the minimum.

The IAEA groups 173 states (IAEA, 2021) from all over the world and produces its Safety Standard, “which provide the fundamental principles, requirements and recommendations to ensure nuclear safety”. Furthermore, the agency has various databases to share a variety of information on the uses of nuclear power: the lessons learned approach and shared knowledge are at the basis of the nuclear sector. An example is the IAEA online incident reporting system (WB IRS) which is an international system jointly operated by the IAEA and the Nuclear Energy Agency of the Organisation for Economic Cooperation and Development (OECD/NEA). Events considered important to safety are submitted into the system and all member countries can access the information to improve the safety of their plants.

Safety and Quality Introduction

The worst nuclear accident in the UK was the Windscale fire in 1957 (Mirror.c.uk, 2019), the so-called "Britain’s Chernobyl”, considered one of the worst in human history, ranked in severity at level 5 out of 7; the British government estimated that up to 30 people developed thyroid cancer due to radioactive pollution of the environment, but analysis indicates that 240 more people are supposed to have died of cancer-related to Windscale.

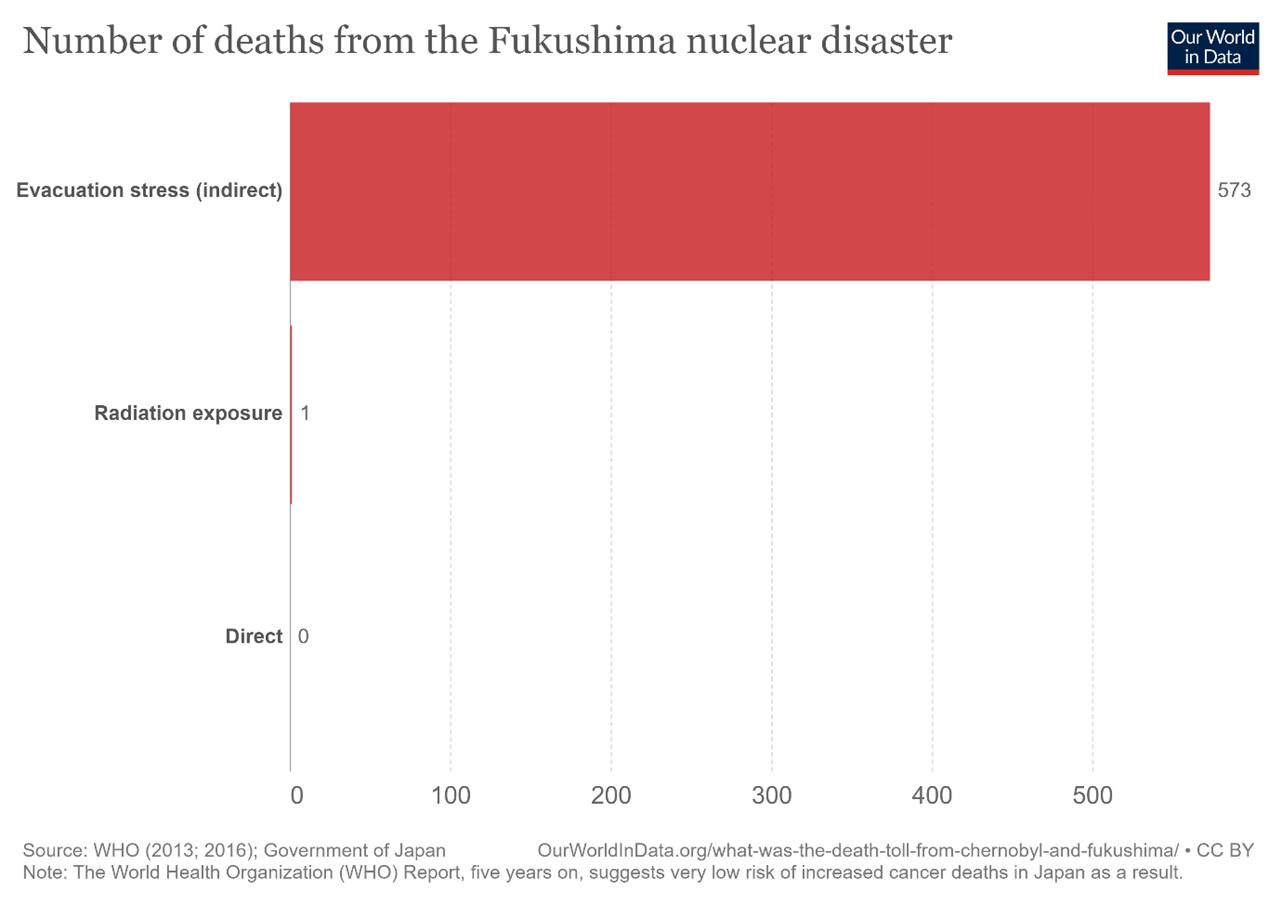

The worst accidents ever recorded in the world are Chernobyl in Ukraine and Fukushima in Japan, both ranked at level 7. Simplifying, Chernobyl was caused by a series of human choices, hidden defects, and poor design; Fukushima was the consequence of an earthquake and a consequent tsunami, causing 1 death due to radiation against the thousands of deaths from Chernobyl.

Just by these numbers, it is evident the progress done over the time.

Furthermore, the construction industry operating within the UK, only reports to itself, the Government and the clients. The nuclear industry, even when operating locally, has huge responsibilities and stakeholders that go beyond the national borders: British authorities, international authorities, people who can be affected by an accident even if they are located hundreds of miles away, economic operators who receive electricity from the nuclear plants, and the people whose energy supply relies on a specific nuclear power plant.

Figure 1 - Nuclear accidents worldwide from 1957 to 2011, rated by the INES scale

(International Nuclear and Radiological Event Scale)

Figure 2 - Deaths from Chernobyl (Estimates) (Ritchie et al., 2020)

Figure 3 - Deaths from Fukushima (Estimates) (Ritchie et al., 2020)

In terms of safety, surprisingly some statistics show nuclear is the safer form of energy in the world. Even accounting for all the major accidents, the number of people who died appears extremely lower compared to the other forms of energy production, including the green sources like solar and wind farms. The table below gives a full view of all the main forms of energy production.

Figure 4 - Mortality rate worldwide in 2012, by energy source - in deaths per thousand terawatt hour (*) (Statista, 2022)

(*) A terawatt-hour is a unit of energy equal to outputting one trillion watts for one hour.

It may now be clear why the nuclear industry adopts more stringent rules for quality management: quality becomes a synonym with safety!

Nuclear Safety

Before analysing the requirements and characteristics of managing quality in the nuclear industry, it is necessary to introduce one of the key elements at the base of the entire management system: “nuclear safety”, not to be mixed with the job-related safety commonly referred to as “HSE – Health, Safety and Environment”.

IAEA defines nuclear safety as “the achievement of proper operating conditions, prevention of accidents or mitigation of accident consequences, resulting in protection of workers, the public and the environment from undue radiation hazards.” (NucSig, 2013). There are other terms and concepts relevant to safety, but the clear message is: all is about safety.

Nuclear activity in the UK can only be undertaken on a licenced, permitted or authorised site (NucSig, 2013). A licence is released with specific conditions, including the management/quality system. Before exploring the latter, a quick look at the players in this industry.

Stakeholders in the nuclear industry

One of the peculiarity of the industry is the number and the level of the stakeholders involved; first of all, the type of customer. In other industries, i.e. the Oil&Gas, the customer may even be a wealthy family who was able to attract enough investments to fund the design and construction of an Oil&Gas plant.

In the Nuclear such a scenario is virtually impossible. The customer usually is a Government operating through companies and the presence of the Government is extremely pervasive, not only for the high-level regulation but also for the importance the infrastructure has and for all the associated risks.

However, the stakeholders’ list is wider and includes (NuclerSig, 2013; updated by the author of this article and for information only):

- International Atomic Energy Agency (IAEA), the principal international organisation publishing standards in the sector

- EU under the EURATOM treaty, even though the UK left EURATOM in 2020 as an indirect consequence of Brexit.

- European Nuclear Safety Regulators Group (ENSREG), a High Level Advisory Group on

Nuclear Safety and Waste Management

- Western European Nuclear Regulator’s Association (WENRA), WENRA formed in 1999, is a network of Chief Regulators of EU countries with nuclear power plants and Switzerland as well as other interested European countries which have been granted observer status.

- World Institute for Nuclear Safety (WINS), provide an international forum for those accountable for nuclear security to share and promote the implementation of best security practices.

- The Institute of Nuclear Power Operations (INPO), was established after the accident at the Three Mile Island nuclear power plant in the USA.

- World Association of Nuclear Operators (WANO)

- Nuclear Energy Institute (NEI)

- Electric Power Research Institute (EPRI)

- The European Atomic Forum (FORATOM)

- Organisation for Economic Co-operation and Development Nuclear Energy Agency (OECD NEA), whose origins date 1948.

- In the UK:

- Office for Nuclear Regulation (ONR).

ONR developed mandatory Site Licence Conditions, “a system of regulatory control based on a robust licencing process by which a corporate body is granted a licence to use a site for specified activities... The nuclear site licence is a legal document, issued for the full life cycle of the facility. It contains site-specific information, such as the licensee's address and the location of the site, and defines the number and type of installations permitted. Such installations include nuclear power stations, research reactors, nuclear fuel manufacturing and reprocessing, and the storage of radioactive matter in bulk.” (ONR, 2022).

These are 36 standard licence conditions covering design, construction, operation and decommissioning. A comprehensive handbook can be downloaded at the ONR website.

- ** Department for Business, Energy & Industrial Strategy (BEIS) for the safe and secure operation of the civil nuclear programme,

- Ministry of Defence (MoD) for the defence programme,

- Department for Environment, Food and Rural Affairs (DEFRA)

- Devolved Governments for waste discharges and disposal

- Foreign, Commonwealth & Development Office (FCDO) take the overview of the non-proliferation of nuclear weapons and represents the UK informal linkages with foreign governments and international organisations such as the IAEA.

- Nuclear Decommissioning Authority (NDA)

- Within the MoD:

- Royal Navy - Fleet Commander & Deputy Chief of Naval Staff

- MoD Defence Equipment & Support (DE&S)

- Defence Safety & Environment Authority (DSEA)

- The Environment Agency (EA) in England, Natural Resources Wales and the Scottish Environment Protection Agency (SEPA) regulate the routine discharge and disposal of nuclear waste and other radioactive material.

- UK Health Security Agency (UKHSA) & the National Arrangements for Incidents involving Radioactivity (NAIR)

- The Food Standards Agency (FSA)

Each of these subjects has specific purposes and was born in the 1940s’ or later. The main aim for all is to share knowledge and ensure nuclear safety is always a priority.

There are also two conventions to be mentioned. The Convention on Third Party Liability in the Field of Nuclear Energy ("the Paris Convention") was established in 1960 under the auspices of the NEA and covers most West European countries; the Convention on Civil Liability for Nuclear Damage ("the Vienna Convention") was established in 1963 under the auspices of the IAEA and is worldwide in character. The UK is a signatory to the Paris convention (NucSig, 2013).

Going into details about each of the above-mentioned organisations, authorities or treaties is not the scope of this article. It was necessary though to highlight how many subjects exist.

An attempt to show the interactions amongst stakeholders is presented below (NucSig, 2013).

Figure 5 - Stakeholder Engagement (NucSig, 2013)

To have an idea of the strong links between operators/contractors and the surveillance/regulator bodies, here below are some examples of issues reported by the French nuclear regulator – ASN – at Flamanville 3 reactor, in France (NucSig, 2013).

| Topic | Issue | EDF / ASN Response |

| 01 April 2008 - Overview | Subcontractors’ technical skills and safety culture |

ANS believe EDF need to reinforce lead and monitoring of activities till shown satisfactory. |

| …. | …. | …. |

| 02 June 2008 - Concreting & Management supervision |

|

Repeated issue – EDF to:

|

| 03 June 2008 - Concreting & Quality Management System |

Authorise resumption of concreting after:

|

EDF to submit a monthly report on the implementation of the action plan. |

| 04 November 2008 - Liner plate welding | Use of different welding methods from those defined in technical specification |

Figure 6 - Examples of issues arisen and reported by the French nuclear regulator ASN at the Flamanville 3 reactor

Note: the above is only a summary. In the period April-November 2008 alone, there were 7 issues reported

What are the basics of the quality management system in the nuclear industry?

From the point of view of design and construction only, the main elements are:

- Certified quality management system

- Personnel qualification and monitoring

- Quality plans and inspections and test plans

- Strict Procurement control via:

- Suppliers’ and Subcontractors’ approval

- Continuous surveillance

- Material controls

Certified quality management system

As IAEA declared on their website “an effective and sustainable management system at a nuclear facility integrates such issues as safety, security, safeguards, health and quality, to ensure that strategic decision making does not take place in isolation.” (IAEA, 2022) Evidently, the ISO9001 is not the only choice, and possibly not even the primary one.

Beyond ISO9001

IAEA Safety Standard series

IAEA issues safety guides for the nuclear industry. As an example, the Safety Standards Series No. GS-G-3.5 “The Management System for Nuclear Installations” contains detailed recommendations also about quality in relation to nuclear installations, and it is applicable throughout the lifetime of a nuclear installation, including site evaluation, design, construction, commissioning, operation, and decommissioning. It can be downloaded for free from the IAEA website.

ASME NQA-1

The American Society of Mechanical Engineers (ASME) developed the nuclear quality assurance standard NQA-1, initially for the USA market but then it was accepted internationally. The standard is comprised of 18 requirements and addresses the full scope of nuclear facilities and activities. However, the focus is on assuring item conformance to technical requirements rather than providing requirements for a total management system. A documented quality assurance programme is required rather than a management system, so leaving out elements critical to IAEA like leadership and culture for safety.

National regulations and standards

System management or quality assurance are not considered consistently a unique management system. Some of the States belonging to IAEA (Member States) refer to quality assurance requirements, others to integrated management systems but without mentioning quality assurance in detail.

The table below offers a view of the different types of requirements and which are considered legally binding.

Figure 7 - Hierarchy of legal requirements, regulations and standards and the bodies issuing them (IAEA, 2020)

However, when a Member State does not require compliance with a standard, the choice often falls on a management system in accordance with ISO9001, enhanced by country-specific requirements.

Specifications, codes and standards: collateral risks

The UK nuclear industry utilises international or USA codes as part of the design process. These may also be supplemented or replaced entirely by the licensees’ own standards. For the UK EDF EPR projects (as an example, HPC in Bristol), the Design and Construction Rules for Mechanical & Electrical Components of Nuclear Islands are detailed in the RCC-M & RCC-E codes which are part of the collection of design and construction rules for nuclear power plants.

Chosen standards may be unknown to the design company and the supply chain. Implications are not only about safety compliance but also about the costs of complying with the strict requirements:

- The design may need to be tailored against the regulatory requirements

- There could be the need to qualify the supply chain against the RCC-x requirements, to ensure the suppliers have enough knowledge of the expectations and are quoting appropriately

- The inspection process may change, up to planning for a full-time inspector deployed at the supplier’s workshop to ensure the smooth progress of the manufacturing process.

- The supply of raw materials can be affected, due to the fact that some requirements may be based on the country of origin of the relevant code/standard where requested materials are common.

ISO19443 – Quality Management in the Nuclear Supply Chain

This ISO standard is relatively new: it was released in 2018 and it enhances the requirements of the ISO9001 specifically for the supply chain of the nuclear sector by including IAEA requirements and sector-specific requirements. ISO19443 supplements ISO9001 but does not replace it.

Figure 8 - Evolution of the IAEA approach to quality, leadership and management showing the organisational management system and detailed quality requirements levels. (IAEA, 2020)

(*) The calls-out in the squares on the right of the curve shows the series of documents issued and the relevant date.

Figure 9 - A high-level illustration of connections between quality assurance, quality control and the management system of nuclear facilities.

ISO 27001 – Information Technology

Why IT certification and information technology, in general, is so important? Simply put: in nuclear the level of secrecy can go up to “top secret”, so that the possibility of external attacks to steal information and the proper management of it during all the operations of the company become of utmost importance.

In construction, people may be used to writing an email, reviewing it, and sending it to the recipient.

In nuclear, each email is sent through the company client and some companies require a classification based on the type of content the message. If the information is only commercial and its knowledge is not restricted, the message can be labelled as “Official” and undergoes a minor form of data protection. However, the higher and more sensible the information is, the higher the restrictions applied to the message are, i.e. for a message with sensitive nuclear information, encryption to external recipients can be applied and external recipients must be preapproved.

The above does not only protect from external attacks but also human errors: the sender must be trained and aware of what type of information is sharing and who the recipient must be.

Another point about information protection is the need not to print documents, if not strictly necessary, and always maintain strict control. Data loss either in the form of electronic files or hard copies is strongly fought.

Security vetting

Access to offices with a badge is common practice: a new employee receives a badge or/and a fob - a small security hardware device with built-in authentication used to control and secure access to the office (webopedia.com, 2021).

In nuclear, the release of the badge is linked to the level of security clearance the individual is granted. A security check is requested, depending on the personal situation and the type of information to manage.

The process to run checks on an individual is valid for those “with access to government assets” (Gov, 2022), so it could also apply to construction personnel. However, the type of information usually managed in a non-nuclear construction project does not involve any critical risk or any secrecy; on the contrary, even a small project in nuclear may require access to information not to be shared outside. The security vetting includes (but is not limited to) the following clearance levels are:

- Baseline Personnel Security Standard (BPSS)

The standard for the pre-employment screening of individuals with access to government assets (Gov, 2022).

Without going into details, they are used, as an example, for individuals with long-term, frequent and uncontrolled access to Secret assets and/or occasional and supervised access to Top Secret ones (Gov, 2022).

- Developed Vetting (DV)

For frequent and uncontrolled access to Top Secret assets.

It allows regular uncontrolled access up to SECRET assets and occasional, controlled access to TOP SECRET assets.

People with different levels of access to information can work together in a company, so it is critical to be able to segregate the information and prevent unauthorised/unintended access or sharing of it.

Suitably Qualified Experienced Person (SQEP)

In addition to health and safety on site, all personnel whose role may have an impact on nuclear safety must be judged to be competent to undertake their assigned tasks (NucSig, 2013). So, such people shall be appropriately trained, monitored, and assessed regularly. Depending on the role, the assessment can be more “light”, only considering a few skills that may be strictly necessary; or there could be a long list of skills in different areas (commercial, engineering, contract management) that the individual is requested to be assessed against. As an example, the assessment of a young engineer will not be alike the report for who is in the position of Project Director. The company may decide what is the minimum acceptable score to be considered experienced in a specific activity.

Assessments should be run periodically, and records kept.

The natural consequence of this review is defining if and what training each worker needs to receive.

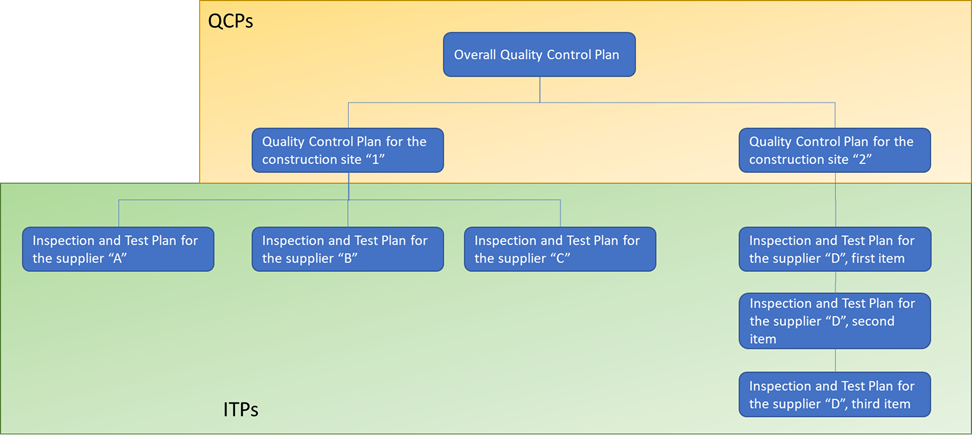

Quality Control Plans and Inspection and Test Plans

The activities are usually covered by one or more quality control plans and one or more inspection and test plans.

The main difference is that the quality plans focus on the quality assurance part of the work (IAEA, 2020) while the inspection and test plans focus on product quality (IAEA, 2020): fabrication, assembly, inspection, and testing (either in a workshop or at the construction site).

The number of QCPs and ITPs depends on the structure of the project and the scope of work. If the project is an engineering-procurement-construction one, with different construction sites and multiple suppliers, there may be one Overall QCP to cover all the main activities of the project. Then, one more QCP for all the activities to be completed for each construction site; furthermore, one or more ITPs for each supplier. A possible structure of the QCPs and ITPs is shown below.

Figure 10 - Structure of the QCPs and the ITPs in a hypothetical project

Suppliers’ evaluation

To be a supplier in the nuclear sector it is critical to be able to prove the ability to deliver the expected item – good or service. As for other industries, there are qualification processes in place to be included in the supply chain. By now it should be clear, though, that this inclusion comes with a cost in terms of commitment and resources.

A supplier needs to undergo a risk assessment that will evaluate its capabilities to deliver in the circumstances under which the job shall be done. For this purpose, a supplier may be examined as follows:

- Commercial appraisal

- Technical appraisal

- Audit

- References’ review

- Clarification meetings

- Quality assessment

All the above can be preliminary to be accepted in the list of approved suppliers but more is requested to bid for a specific job. In such a case, the review goes into more details, like:

- The organisation chosen to deliver the work (for examples joint venture or temporary association)

- Level of subcontracting. There could be limits to the number of tiers involved in a project. So, a bidder may need to consider if the whole job can be completed without involving various tiers of subcontracts. Eventually, the bidder may be “forced” to create joint ventures with one or more of the suppliers, so to work as one entity – the joint venture - instead of a “contractor-subcontractor” setting.

In some cases, a list of preferred suppliers may be used by the clients. However, under the Public Contract Regulations, those lists may not be allowed, so to leave the possibility to all companies to compete and ensure transparency of the procurement process.

Suppliers’ qualification

“To avoid inappropriately applying overly prescriptive controls to non-nuclear safety-significant tasks, a grading approach is used. This allows due rigour to be applied to those activities that truly are safety-significant and lesser control to those that are less significant. The outcome of such grading is integral to almost everything that occurs related to the plant and operators” (NucSig, 2013).

Going into more details, the IAEA GSR Part 2 “Leadership and Management for Safety” (IAEA, 2016) “requires the operating organisation to retain responsibility and to include in its management system arrangements with its suppliers for specifying, monitoring and managing the supply to it of items, products and services that may influence safety. It specifically requires these arrangements to include qualification, selection, evaluation, procurement, and oversight of the supply chain. The organisation, furthermore, needs to make arrangements for ensuring that suppliers of items, products and services important to safety adhere to safety requirements and meet the organisation’s expectations of safe conduct in their delivery. This principle also includes the idea that the applicable requirements need to be cascaded to the sub-contractors in the supply chain.” In a few sentences, the summary of how complex the supply chain management may become.

To make all the system more complicated – but necessary to reach higher standards of safety – the items to be purchased can be classified as:

- COTs – commercial off-the-shelf items. It is the most common type of item, mainly all those that can be bought directly from a seller or reseller without modifications against the manufacturer’s specifications

- MOTs – modified or modifiable off-the-shelf items, or military off-the-shelf.

- Bespoke – an item manufactured according to the requirement of the client, so customised at a level to have a single-use.

However, for inspections performed by robots, the Nuclear sector seems moving toward COTs/MOTs items, so trying to keep them “as expendable elements in more flexible systems, providing cheaper and higher technology readiness level products quicker.” (Smith et al., 2020)

It is evident that, if a project is based on COTs items, the costs are lower, and the management easier:

- The items may not require further inspections than those performed by the manufacturer

- The items may be more easily available on the market

- There is a history of performance for each item that may help the project team choose the best solution.

Quality Grades

Nevertheless, all the above is true if we exclude the other classifications in use in the nuclear industry: the quality grade assigned to each item. The nuclear plants’ operators use different levels of inspection depending on an assessment that takes into consideration, amongst other criteria, the impact the failure of an item may have on the nuclear safety. When nuclear safety may be a concern, the category assigned to the item is the highest. Then, there are two more levels where the requirements decrease, and a final one where there are no specific requirements above what the manufacturer usually does.

Sellafield offers the following classification:

| Risk | Description | Quality Grade | Description |

| Very High | Failure may lead directly to serious radiological risk. | QG01 |

Inspection at Supplier’s Works required by Inspection & Certification Group (ICG) in line with SLM 4.06.02 Contract Quality Requirements. A Quality Plan is required. |

| High | Failure may lead directly to an incident that must be formally reported to an external body such as the Office for Nuclear Regulation (ONR) Environmental Agency (EA) or Health and Safety Executive (HSE). Failure is likely to result in major economic consequences. | QG02 |

Inspection at Supplier’s Works required by Inspection & Certification Group (ICG) in line with SLM 4.06.02 Contract Quality Requirements. A Quality Plan is required. |

| Medium | Failure may lead directly to an internally reportable incident. Failure is likely to result in minor economic consequences. | QG03 |

Receipt inspection only by Inspection & Certification Group (ICG) in line with SLM 4.06.02 Contract Quality Requirements. Note: A Quality plan is not mandatory but may be requested by exception. |

| Low/no risk | Failure is unlikely to lead directly to a reportable incident of any kind. Failure is unlikely to result in more than trivial economic consequences. | QG04 |

No formal inspection other than check for transit damage and order completion. Only to be used for items that if Failed on delivery or utilisation would have Low to No implications with regard to Nuclear/Radiological safety, Conventional safety, Environmental impact, Business risk. The product or service carries low/no risk. The flow-down of the Sellafield Ltd Contract Quality Requirements is no longer required as there are no applicable requirements for a QG04 product or service and industry best practices for managing and delivering the product or service should be applied. |

Table 2 - Sellafield risks and quality grades

“Flow-down” refers to the need to share/impose Sellafield’s requirements to the lower-tier subcontractors: all tiers where the risk associated with the product or service continues to be a QG01, 02, or 03.

Safety Case

Another point is the Safety Case, referred to by the Safety Assessment Principles developed by the ONR – Office for Nuclear Regulation, which “encompass the totality of the documentation developed by a designer, licensee or duty-holder to demonstrate high standards of nuclear safety and radioactive waste management, and any subset of this documentation that is submitted to the Office for Nuclear Regulation (ONR)”.

Where the items are identified in the Safety Case, the Safety Function Class (SFC) and/or the Safety Designation shall be identified in the purchase order. The relation between SFC and QG is as follows:

- SFC1 - Quality Grade 01

- SFC2 - Quality Grade 02

- SFC3 - Quality Grade 03

- Safety Mechanism - Quality Grade 02

- Safety Related Equipment - Quality Grade 03

The project activities can face hard times trying to classify every item based on all the above requirements. The impact of each choice can be huge: realising that an item initially classified in a lower category must be upgraded can cost in any sense of the word: money, time, rework, rebid.

Quality Related Activity

Quality Related Activity (QRA) requires more stringent requirements for Safety Classified Products. A Quality Related Activity is “an activity, the failure of which can lead to a product non-compliance with the nuclear safety requirements” (NucSig, 2013).

Counterfeit, fraudulent, and suspect materials

Dealing with material appropriately certified is critical in any industry, as described in the relevant CQI article on CFSI.

In nuclear, the “CFSI – Counterfeit, fraudulent, and suspect materials” policy is part of the procedures of any company and is usually attached to the purchase order released to the supply chain.

No chances are taken: if any material is suspected to be not appropriately certified or falsely certified, apart from being rejected and the supplier investigated by the customer, there could be a report shared in the industry to make all operators aware of the risks of using such materials. The alert system is a good deterrent for those thinking it could be beneficial to them to decrease the levels of control on the material; when caught, the company brand can be heavily impacted.

Some examples of organisations that communicate and share relevant information are:

- IRS — The IAEA International Event Reporting System.

- WANO/INPO — Website and NUPER database where event reports can be scanned (open to Members only).

- CANDU Owners' Group (COG) Information Exchange System.

Obviously, CFSI does not imply necessarily intent or knowledge of wrongdoing. Nonetheless, the vigilance on the materials supply is kept at a high level.

The MoD Defence Equipment and Supply (DE&S) group has a dedicated team overseeing issues relating to suspect materials.

Fighting against CFSI is not only a procurement or inspection duty. It starts with the design of the plant, to be sure that all materials requirements are clearly stated, and appropriate certifications are identified.

IAEA (2000) provides a list of examples collected from experience:

- Nameplates, labels, or tags have been altered, photocopied, or painted over; are not secured well; are unusual in location and method of attaching; show incomplete data; or are missing. Pre-printed labels normally show typed entries.

- Item has worn marks or scratches on external surfaces.

- Obvious attempts at repair or re-conditioning have been made: excess painting or wire brushing, evidence of hand painting (touch-up), painted stainless steel.

- Handmade parts are evident; gaskets are rough cut; shims and thin metal part edges show evidence of cutting or dressing by hand tools, for example filing, hacksaw marking, tin snips, or nippers

- Hand tool marks exist on fasteners or other assembly parts; upset metal exists on screw or bolt head or dissimilar parts are evident; seven or eight bolts are of the same material and one is of a different material.

- Assembled items fit poorly.

- Metallic items are pitted or corroded.

- Casting markings have been ground off and the item has been re-stamped with other markings.

- Configuration is inconsistent with other items from the same supplier or varies from that indicated in supplier literature or drawings.

- Component or item is unusually boxed or packed.

- The supplier is not a factory-authorized distributor.

- Dimensions of the item are inconsistent with the specification requested on the purchase order and those provided by the supplier at the time of shipment.

- Item or component matches the description of one that is on a Member State list of S/CIs.

A critical point of CFSI materials is the need to identify and mark them as not to be used. One of the examples from IAEA shows that CFSI high strength fasteners were not properly marked as CFSI and were not removed from the bill of materials, thinking that they could have anyway been used where lower strength bolts are accepted. However, missing a correct identification of the CFSI bolts may lead to confusion about where they can be used, bringing them back by mistake in high strength applications.

Even when the bolts had been hand-marked to indicate the problem, though, a different situation might have happened: mismatch with the manufacture documentation and potential issues later.

The best option seems to reject CFSI instead of trying to save a few pounds.

Software validation

A word must be spent on the need to ensure that software development follows sound practices and the relevant ISO standard.

The use of commercial software is accepted. However, if the software is produced by the contractor themselves, then additional requirements on how to proceed are imposed by the client.

Independent assessment

Besides the review cycle for each deliverable issued on a project, risk reviews, audits, third party inspection, and peer review; chances are that one or more independent reviews from an external company will take place. The scope is to assess the effectiveness of the management system and propose improvements.

As we reported above, working in the nuclear sector also implies using regulations from other countries (such as the RCC-M), so the independent assessment also becomes a way to ensure that all the efforts done are producing the expected results.

Business Continuity Plans

All the foreseeable events need to be considered and, possibly, go even beyond. So, it is important to develop business continuity plans which, as the name suggests, contain information about how to ensure that the company can progress in a number of circumstances that can happen. As an example, in the event of a shortage of workers in critical functions.

A word on the timescale

One more characteristic of the nuclear industry, which contributes to its uniqueness, is the peculiar timescales. Before starting a new nuclear plant, obtaining all the permits, getting the funds, designing, constructing, and commissioning the plant require decades. Decommissioning – in simple words, switching off the plants at the end of their lifetime and dealing with the contaminated materials – may require more than a hundred years. At Sellafield, for instance, there is still a further 110 years of work planned simply to address the existing liabilities.

Furthermore, at least in the UK, the industry evolved from a centrally directed one to a relatively fragmented one. Many different organisations exist that need to work closely together and share what they know to ensure a successful national programme. Huge efforts are necessary, from managing the supply chain to maintaining and developing appropriate competencies.

The latter requires that knowledge is transferred from generation to generation of nuclear operators and specialists, considering that the full life cycle of a given facility usually exceeds any one individual’s career and that for an individual to become competent in the industry may need a longer time than other industries – long training, higher qualifications, and continuous learning.

Timescale plays a critical role also in the records retentions. There are requirements for the licensee – a corporate body is granted a licence to use a site for specified activities – to maintain records for 30 years; in some cases, for 50 years, to demonstrate the compliance with the site licence conditions.

Conclusions

The nuclear industry is a challenging environment, where nothing can be left to the fate. Highly regulated, highly supervised, technologically challenging: all elements that may raise the interest of the brave or put down the enthusiasm of the less experience ones.

With the famine of energy, the world is moving towards new nuclear power plants, and the UK seems to be leading this new approach.

If the plans are confirmed by the Government, there will be almost twenty new power plants in the UK. It is to be noted that a good chunk of the activities involves civil works. If on one side the sector requires commitment, on another it can be full of opportunities for those willing to invest. Furthermore, plans to involve small-medium enterprises are usually part of the realisation of a power plant. As an example, EDF in Bristol actively incentivises the participation in the ongoing construction activity by small SMEs and monitors the market, reporting statistics about different areas of the UK and the total value of the contracts awarded.

References

- Gov.uk (2022). Guidance. National security vetting: clearance levels. https://www.gov.uk/government/publications/united-kingdom-security-vetting-clearance-levels/national-security-vetting-clearance-levels?msclkid=3c414fd0af5411ec9720442695b40184

- IAEA (2000). Managing Suspect and Counterfeit Items In The Nuclear Industry IAEA, Vienna, 2000 IAEA-TECDOC-1169 ISSN 1011–4289 https://www-pub.iaea.org/MTCD/publications/PDF/te_1169_prn.pdf

- IAEA (2022). IAEA – International Atomic Energy Agency. https://www.iaea.org/

- IAEA (2022). IAEA – International Atomic Energy Agency. Management systems for nuclear facilities. https://www.iaea.org/topics/management-systems?msclkid=011cedb3b04411ec90bf3980fbc1d934

- IAEA (2020). Quality Assurance and Quality Control in Nuclear Facilities and Activities. Good Practices and Lessons Learned. https://www.iaea.org/publications/13656/quality-assurance-and-quality-control-in-nuclear-facilities-and-activities?msclkid=011d90ddb04411eca84b10f88395975c

- IAEA (2016). GSR Part 2 “Leadership and Management for Safety” https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1750web.pdf

- Laka.org (2022). Laka – Documentation and research centre on nuclear energy. https://www.laka.org/docu/ines/location/africa]

- Mirror.co.uk (2019). The Windscale Fire: Britain’s #Chernobyl” which was ‘covered up’ for decades. https://www.mirror.co.uk/news/uk-news/windscale-fire-britains-chernobyl-covered-15774677?msclkid=748ac71faeb011ec8ded02ff3d8aecf9

- NucSig (2013). Chartered Quality Institute, Nuclear Interest Group - Nuclear Quality Knowledge (NQK) Version 2 – 2013. https://www.nuclearinst.com/write/MediaUploads/Resources/NQK2013.pdf

- ONR (2019). Guide. The purpose, scope, and content of safety cases. NS-TAST-GD-051 - The Purpose Scope and Content of Safety Cases (onr.org.uk)

- Ritchie, H., Roser, M., Rosado, P. (2020). "Energy". Published online at OurWorldInData.org. Retrieved from: 'https://ourworldindata.org/energy' [Online Resource]

- Smith, R., Cucco E., Fairbairn, C. (2020). Robotic development for the nuclear environment: challenges and strategy Robotics, 9 (2020), p. 94, 10.3390/robotics9040094

- Statista (2022). Mortality rate worldwide in 2012, by energy source (in deaths per thousand terawatt hour). https://www.statista.com/statistics/494425/death-rate-worldwide-by-energy-source/?msclkid=b3fd8abcaebf11ecaa6562c4fc624b08

- Webopedia (2022). Vangie Beal. Key Fob. https://www.webopedia.com/definitions/key-fob/#:~:text=A%20fob%2C%20commonly%20called%20a%20key%20fob%2C%20is,changes%20periodically%20usually%20every%2030%20to%2060%20seconds.?msclkid=89a05177af5211ec9f621392989e126f

- WHO (2005). World Health Organisation - Chernobyl: the true scale of the accident. 20 Years Later a UN Report Provides Definitive Answers and Ways to Repair Lives

https://www.who.int/news/item/05-09-2005-chernobyl-the-true-scale-of-the-accident

This article was originally written by Giorgio Mannelli on behalf of the CQI Construction Special Interest Group, reviewed by Keith Hamlyn and Colin Harley, members of the Competency Working Group and approved for publication.

16:12, 09 Jan 2024 (BST)

Related articles on Designing Buildings

Featured articles and news

One of the most impressive Victorian architects. Book review.

RTPI leader to become new CIOB Chief Executive Officer

Dr Victoria Hills MRTPI, FICE to take over after Caroline Gumble’s departure.

Social and affordable housing, a long term plan for delivery

The “Delivering a Decade of Renewal for Social and Affordable Housing” strategy sets out future path.

A change to adoptive architecture

Effects of global weather warming on architectural detailing, material choice and human interaction.

The proposed publicly owned and backed subsidiary of Homes England, to facilitate new homes.

How big is the problem and what can we do to mitigate the effects?

Overheating guidance and tools for building designers

A number of cool guides to help with the heat.

The UK's Modern Industrial Strategy: A 10 year plan

Previous consultation criticism, current key elements and general support with some persisting reservations.

Building Safety Regulator reforms

New roles, new staff and a new fast track service pave the way for a single construction regulator.

Architectural Technologist CPDs and Communications

CIAT CPD… and how you can do it!

Cooling centres and cool spaces

Managing extreme heat in cities by directing the public to places for heat stress relief and water sources.

Winter gardens: A brief history and warm variations

Extending the season with glass in different forms and terms.

Restoring Great Yarmouth's Winter Gardens

Transforming one of the least sustainable constructions imaginable.

Construction Skills Mission Board launch sector drive

Newly formed government and industry collaboration set strategy for recruiting an additional 100,000 construction workers a year.

New Architects Code comes into effect in September 2025

ARB Architects Code of Conduct and Practice available with ongoing consultation regarding guidance.

Welsh Skills Body (Medr) launches ambitious plan

The new skills body brings together funding and regulation of tertiary education and research for the devolved nation.

Paul Gandy FCIOB announced as next CIOB President

Former Tilbury Douglas CEO takes helm.